- MacLean

- Engineering Services

Engineering Services

Diverse Solutions for Every Industry Need

From manual to actuated valves, pumps, and accessories, through to maintenance, repair, machining, general fabrication and welding, MacLean International delivers the solutions your project demands.

Our Engineering Services team operates across numerous industry sectors such as onshore Oil and Gas, Energy, and Agriculture. We offer full valve support with bespoke modification and are equipped with the resources, equipment, and seasoned expertise to handle both extensive, intricate projects and straightforward off-the-shelf solutions, catering to the most stringent of turnaround schedules.

Our engineering services combined with a dedicated team of experienced service engineers, actuation specialists, trained technicians, and our ISO 9001:2015 accredited processes ensure we can offer you full technical and product support for the lifetime of your assets.

Valves & Associated Services

Total Valve Solutions (TVS) is our complete valves solution offering engineered actuation packages combined with the highest quality valves, servicing, maintenance and repair. Extending the life of your assets and minimizing downtime are the driving forces behind this solution.

Industrial Sales & Technical Support

As a major distributor of manual and actuated valves and specialized installer of valve actuators, we not only have a comprehensive local inventory, but also have access to an impressive global stock via parent company DistributionNOW.

Benefitting from DNOW’s extended global reach and extensive distribution network, MacLean International’s sales team can provide what you need, when you need it. Our dedicated team of product experts combined with our established supplier relationships with globally renowned manufacturers, means we can offer technical expertise to guide your product selection.

Automation & Actuation

Ideal for use in applications in hazardous areas or where valves are located remotely you can choose from manual, pneumatic, hydraulic, gas over oil or electric actuators to power your valve function.

We offer comprehensive actuation for almost any application and can customize automated systems to suit.

Actuator design and modification is also available from our in-house facility and team of engineering experts to meet your specific project demands.

Service, Repair, Modification & Maintenance

Accommodating fast track projects and critical plant shutdowns we offer a wide range of service, repair, modification and maintenance options from our teams of highly experienced engineers and OEM trained technicians. Working to ANSI and API standards, whether in the field or within our impressive in-house workshop and machining facility, our 24/7 service handles simple to complex modifications, planned and unplanned maintenance, and everything in between to ensure your assets are properly and safely maintained:

- Site evaluation and repair assessment

- Strip down and inspection

- Valve refurbishment (for Turnaround campaigns & unplanned maintenance outages)

- Valve criticality ratings and strategy establishment

- Planned obsolescence strategy and planning

- Repair/upgrade recommendations

- Pressure testing & recertification

- Calibration and Recalibration

- Reconditioning

- Field service & Maintenance

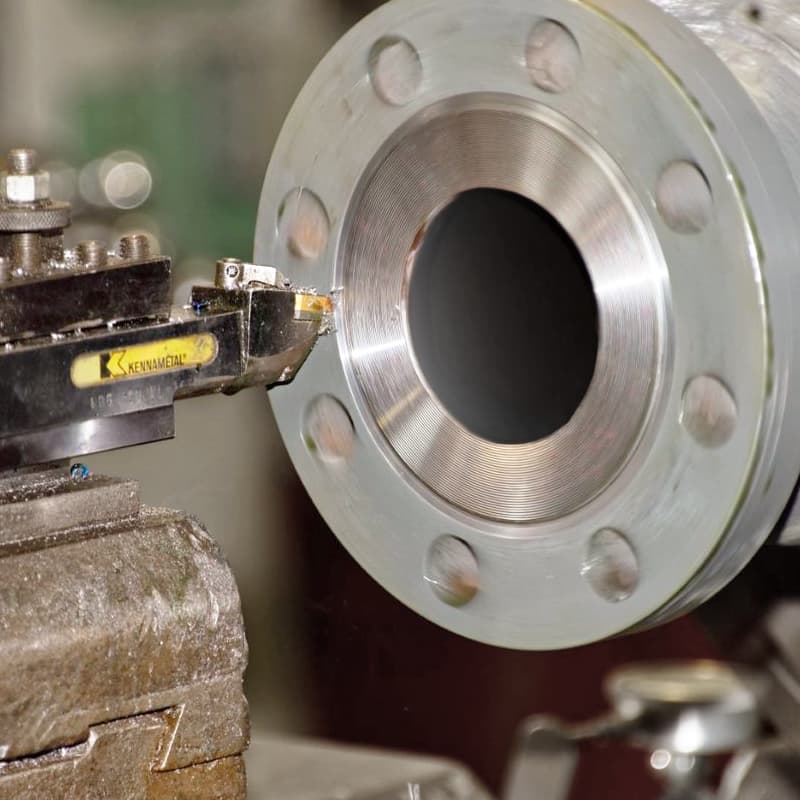

Machining

Situated in Roma, Australia our full-service, engineering facility provides all general and oilfield precision machining to API standards, however our continual investment in CNC machines and testing units consistently ensures we exceed many industry and customer standards.

Our large-scale warehouse holds an impressive inventory of valves, actuators, pumps and accessories and our engineering workshop houses an array of state-of-the-art industrial machinery for servicing high and low pressure pipe fabrication work, vessels, skid packages, hydro testing and sand blasting and on-site welding and installation:

Machinery

- CNC Lathes

- Lathe CNC Goodway –

- for pipe, tubing and API connections

- max diameter through spindle 180mm

- includes live tooling

- suitable for manufacture of flanges etc

- max turning diameter of 750mm inside machine

- Oilfield Manual Lathe – 12” suitable for:

- oilfield machining

- repairs

- chase & face tubing/pipe Orifice plates

- flanges

- spec blinds up to 60”

- DOT Mark Stamping Machine

- Cosen C-300NC Bandsaw, hitch feed

- Thread Gauge’s (full range API standard)

- Hydraulic Gauge Press (100 and 60 tonne)

- Milling Machine

- Radial Arm Drill

- Drills and dies to 2” capacity

- Broaching/Keyways set 1/8” – ¾” capacity

- Lathe CNC Goodway –

Vertical Centre Nexus (Mazak)

With a quick tool-to-tool change time of just 2 seconds, active vibration control and a 4th Axis rotary head, this impressive piece of equipment within our in-house engineering facility:

- Is designed to achieve high torque machining and productivity

- Has a 50-taper, 30HP, 6,000 RPM spindle with 665 ft-lbs of torque

- Includes active vibration control to ensure high-accuracy motions in all axes, reduce machining time and produce high quality machine surface finishes

- X x Y x Z axis strokes of 80” x 27.6” x 28.4” allows expanded machining envelope and improved heavy duty cutting capabilities

Machined Items

- EUE and NUE Connections

- NPT Connections

- API Relief

- Bore Back Box

- ID Bands & Stamping

- Sucker Rod Inspections

- Float Subs

- EUE Pump Out Plugs

- Companion Flanges & Spectacle Blinds

- Wellhead Adaptors

- Victaulic Gooves

- Bundle Carriers

- Gauge Carriers

- Orifice Plates

- Bullnose Perf Subs

- Lift Subs