- Products & Services

- Process & Production Equipment

- Launchers & Receivers

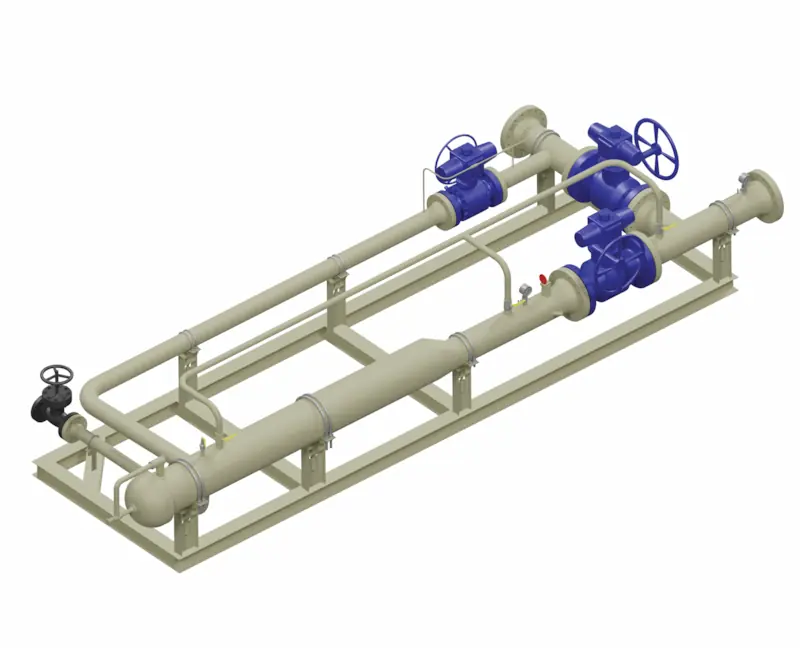

Launchers and Receivers

DistributionNOW Process Solutions group offers pigging launchers and receivers built to any specification and size. Our in-house design, engineering, fabrication and testing capability produces various pig and sphere launching and receiving systems.

Product Description

DNOW keeps your pipelines running smoothly with high-quality pigging launchers and receivers. We have everything from basic designs to advanced, high-tech solutions to ensure your pipeline operations run smoothly. Whether you need a simple pig trap or a complex system with multiple vessels, we have you covered.

Features

- Versatility: Our launchers and receivers can be used with various pipeline pigs, including foam, steel and polyurethane pigs.

- Durability: Our products use only the best materials to ensure maximum durability and longevity.

- Safety: We design safety features such as pressure relief valves, safety interlocks and emergency shutdown systems.

- Ease of use: Pipeline pigging operations can be carried out quickly and efficiently with quick-opening closures and removable covers.

- Customizable: We offer a range of options, such as size, pressure rating and material selection.

Products Offered

We offer a wide range of pig launchers, receivers and associated equipment for large or small-diameter pipelines.

- Barrel launchers and receivers

- Turnkey, skid-mounted designs

- Pig signalers (manual & electric)

- Control systems

- Actuated valves

- Quick-opening closures

- Bi-directional designs

- Conventional and smart piggable designs

- Gas and liquid service

Our Capabilities

| Materials of Construction | Carbon steel, stainless and alloy steel |

|---|---|

| Dimensions | 4 in. - 48 in. and custom sizes upon request |

| Pressure Rating | ANSI 150 - 1500 |

| Non-Destructive Testing | Ultrasonic, hydrostatic, radiographic, dye penetrant inspection, positive material identification (PMI), hardness and others |

| Finishing | Surface prep, blasting, internal and external coating, painting |